1. Application

The main application of glass enamel is decorating tempered glass (architectural glass,home appliance glass,furniture glass) and auto glass .

2. Tempered glass enamel

Type: architectural glass;home appliance glass;furniture glass

Function:

decoration

conceal the frame of building, electronic component or for showing.

3. Auto glass enamel

Type: Front windshield glass enamel;Rear windshield glass enamel;Side winshield glass enamel and silver paste.

Function:

To prevent ultraviolet radiation through the glass

To prevent the glue used to bond the glass and car occur chemical change

Conceal some conductive lines

Decoration

4. Decorate glass ware

Type: cosmetic bottle,beverage bottle,wine bottle,tableware cup[

Function:

decoration

develop the new product

fix the label

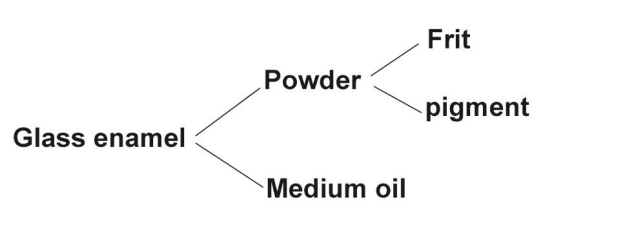

5. The composition of glass enamel

1) The powder of glass enamel: Frit and Pigment

a.Frit: a mixture of silicon dioxide as a main component and melted at a high temperature

b.Function:

sintering performance,the combination of ink and glass

Wear resistance

Chemical resistance

Thermal expansion coefficient

Gloss

a.Pigment: A mixture of metal oxides that can be melted at high temperatures

b.Function:

Color

Hiding powder

2) Glass enamel: the powder of glass enamel ;medium oil

Frit: a mixture of silicon dioxide as a main component and melted at a high temperature

Function:

sintering performance,the combination of ink and glass

3) Medium oil: A mixture of organic compounds

Function: To provide printing performance on glass

6. The method of application

Spraying ; Roller printing ; Screen printing ; Curtain printing

1) Spraying

Advantage:

a. suitable small scale production

b. Can achieve a good printing thickness

c. Ink and water miscible, water cleaning equipment

d. Suitable for all sizes and shapes of glass

Disadvantage:

a. Excessive spraying produces contamination

b. Excessive spraying results in loss

c. Low production efficiency (hand spray)

d. Labor intensity (hand spray)

e. Can not print pattern

2) Roller printing

Advantage:

a. High production efficiency

b. Can achieve high printing thickness

c. Less contamination of the glass edge

d. High yield

e. Suitable for all sizes of glass

f. Clean

Disadvantage:

a. Not suitable for small-scale production

b. Can not print pattern

3) Screen printing

Advantage:

a. Suitable for printing patterns and overprint

b. Do not pollute the glass edges

c. High yield

d. Less ink consumption

e. High production efficiency

Disadvantage:

a. Screen, making pattern costs

b. Low printing thickness

c. Not suitable for small-scale production

4) Curtain printing

Advantage:

a. High production efficiency

b. A high printing thickness is obtained

c. Ink and water miscible, water cleaning equipment

d. Suitable for all sizes and shapes of glass

e. Clean

Disadvantage:

a. Glass edge contamination

b. There is a certain waste rate

c. Not suitable for small-scale production

d. Can not print pattern

7. Printing

A. Printing instructions

1) room temperature (20 ~ 23 ℃) storage ink to prevent precipitation;

2) by adding medium oil, the use of low-speed mixer to adjust the viscosity;

3) to maintain the standard temperature (21 ℃) measured viscosity;

4) diluted, stirring the ink (suspension) standing 30min to eliminate the bubbles generated during mixing;

5) The glass must be clean and dry, keep the same with the printing room temperature;

6) to ensure that the glass is always printed on the same side (tin surface or non-tin surface) to avoid color;

7) measuring the thickness of the printing to ensure that the thickness of the same, the thickness of the change may lead to changes in color;

8) immediately after printing drying to prevent dust adhesion;

9) For overprint, the glass must be returned to room temperature, and then the second color printing.

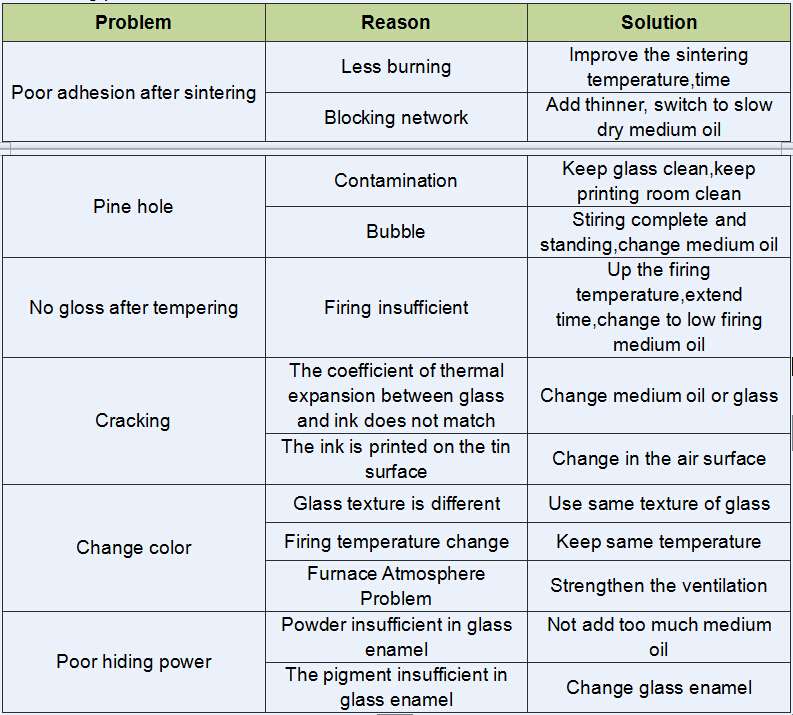

B. Printing problems

8. Drying

1) The method of drying: Infrared drying, UV curing (for automotive glass), hot India (flat cup, bottle)

2) Purpose: A solid print layer was obtained before sintering and stored again.

3) Parameters: wet film thickness, ink evaporation rate, drying speed, drying temperature.

Recommendation: Immediately dry after printing to avoid sticking dust

4) Meidum oil: solvents (such as pine oil, terpineol), polymers, additives (such as surfactants, flow agents, thixotropic agents)

Note: For screen printing with varnish, can provide oil or water-based varnish

Copyright ©2008 Qingdao Caitian Industrial Materials Co., Ltd.

Powered by : HiCheng